How to Choose the Right Trailer Coupler?

time2022/05/26

- Trailer couplers are attachment points mounted on the trailer to attach and secure the trailer to the vehicle. There are many different types of trailer couplers, which are detailed below.

Trailer couplers are attachment points mounted on the trailer to attach and secure the trailer to the vehicle. There are many varieties, but all couplers work by clipping onto the hitch ball, they have different attachments, some have a handwheel to tighten the clip to the ball, and some use a lever or toggle to lock the coupling device.

When the lever is flipped to the locked position, the clip is pulled to the underside of the hitch ball. The fit should be snug, but not too tight, if it is too loose there is a danger of the connector falling off the hitch ball.

Select coupler:

Trailer hitches are rated by weight and are available in 5 grades. It is important to match the trailer coupler and hitch ball to the proper load weight of the trailer. Once you've determined the tongue weight and gross trailer weight and determined the towing capacity of the vehicle, it's time to choose a hitch, there are many different types. Here are a few different types of trailer couplers for you.

Straight tongue/channel style--The coupler has a square tubular mounting sleeve or tongue that can be bolted or mounted to a trailer. Designed for trailers with straight slot tongues or cross bars.

Round tongues--The couplers slide into the round tang tongues and are welded, they have a spring-loaded collar to ensure a snug fit.

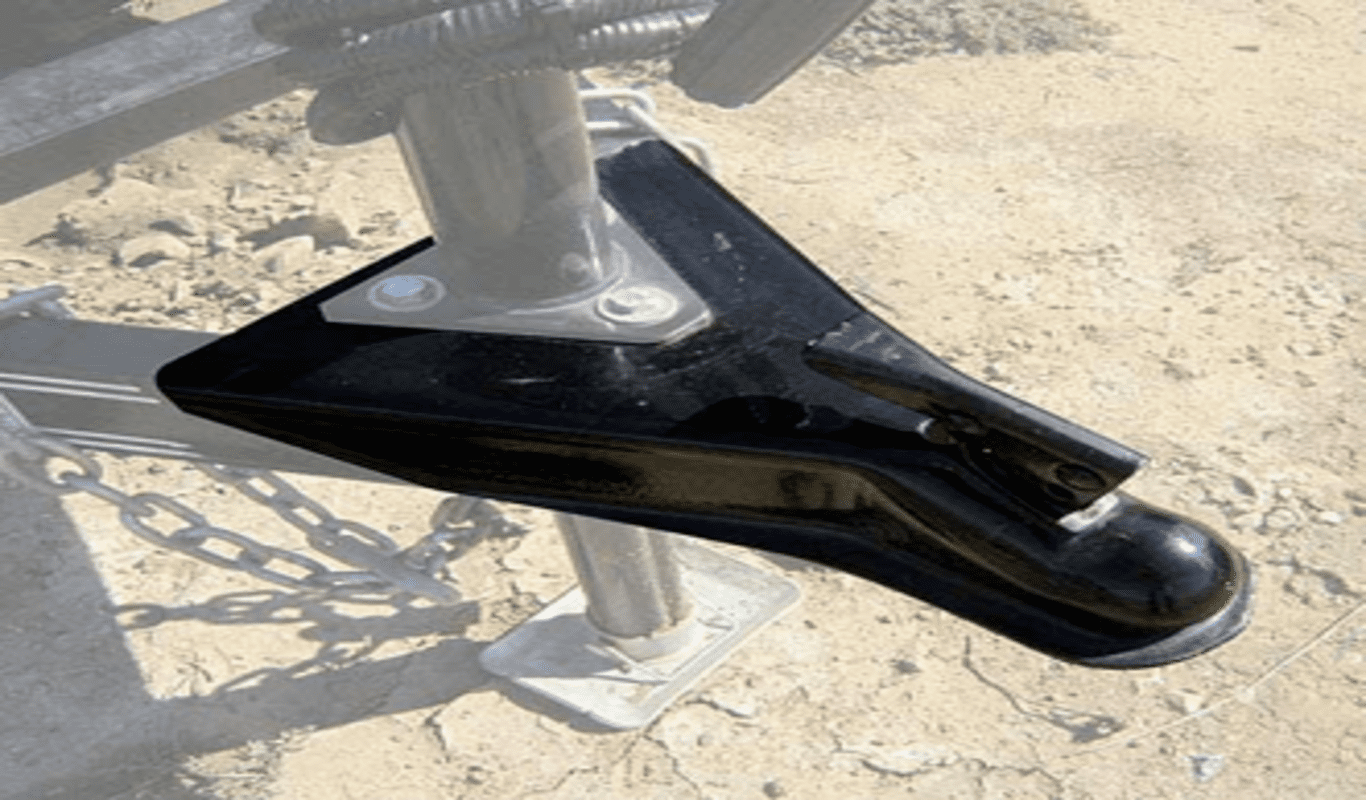

A-Frame--Attached to the A-shaped trailer tongues are sturdy stamped steel couplers for heavier loads.

Flat mount couplers--Instead of channels, the mounting surface is flat and can be bolted or welded. These are used as an alternative to tow rings or pivot hooks, which are mounted on the end of the trailer tongue for heavy-duty trailers.

Gooseneck--Long tubular shaft coupling, used with gooseneck hitches, typically used on heavy-duty trailers such as horse trailers.

Adjustable couplers--Adjustable trailer couplers give users the flexibility to use different sizes or grades of couplers; be able to adjust them up or down to match trailer height, or swap them out for other options such as clevis or pins ring. Channels (4-hole, 6-hole, 8-hole, etc.) are welded directly to the frame, and you can optionally bolt connectors into the channels.

Once you have selected the correct coupler you need, you can install it. If you have a solid grasp of how to install, you can do it yourself, but in some cases where soldering is required, you may have no choice but to install professionally. If you purchase channel or A-frame couplers, you can install them with hand tools.

No matter what you choose, the trailer connector must match the tongue on the trailer. Most of the time the coupler has pre-drilled holes for inserting the mounting bolts, make sure everything is installed correctly before bolting the coupler to the tongue.

A suitable connector will mate with the tongue and allow maximum overlap, basically, the connector you install will be an extension of the tongue, so you have the option of soldering the two components together, however, bolting the two together should provide sufficient strength.

Stay safe and always make sure your equipment is the correct size and installed correctly!

The above has introduced different types of trailer couplers, if you still do not know how to choose or you want to buy trailer accessories, please contact us.

Haway is a professional custom trailer axle and parts supplier in China. Our products are exported to Australia, New Zealand, Canada, the United States, and some European countries. Our factory produces a large number of trailer axles, torsion axles, trailer fenders, trailer jacks, and boat trailer parts. Offering a wide range of trailer parts, Haway has one of the most complete lines of trailer parts.